Advantages of a robot carpenter for the furniture industry

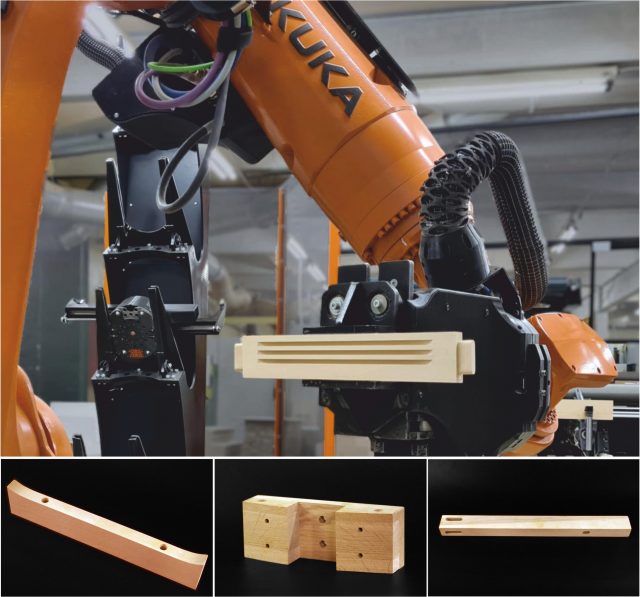

It is no secret that the furniture manufacturing sector is facing a shortage of skilled workers and a complicated search for them. The best and most experienced furniture masters lose their attention and speed over the years, and young workers did not want to choose the carpentry profession. For the reasons mentioned above, manufacturers face the problem of producing more and better products without increasing the number of employees. That’s what RoboMill, the carpenter’s robot, was designed for. The furniture manufacturing company Medienos era has a successful experience in applying this robot.

Here is ways robot carpenter RoboMill helps in furniture production:

• Enables better use abilities of the skilled employees.

• Reduces the need for new skilled workers through company and production expansion.

• Helps to improve product quality.

• Accelerates production time.

Furniture workers can do more working together with a robot. In this case, people will do jobs that require the highest qualifications and creativity. A workplace equipped with a robot will be attractive to young workers – there will be no monotonous and dangerous tasks left. The industrial robot will help attract the next craftsman generation.

A robot performing the function of a carpenter will allow:

• Produce more at the same time.

• Make orders faster.

• Better planning of production flows.

• Reduce losses due to quality problems, i.e., repair of product defects, waste of raw materials, additional work due to customer dissatisfaction.

Use a robot and increase the productivity of an existing team. Such a solution will help much more than just another woodworking machine. Acquiring a robot is a solution that will help you deal with current and future challenges and increase your competitiveness. Solutions that save human resources are the basis of a great future strategy. It is definitely not worth limiting business development for the reason “lack of people”. Robots are worth thinking about for every successful furniture manufacturer who is currently having more orders than can produce. Any order not accepted due to overcapacity is an abandonment of future development opportunities. At present, manufacturers who do not respond well to market demand are losing a significant competitive advantage. Orders not made by one furniture manufacturer will be fulfilled by a competitor. Efficient production processes are one of the most significant competitive advantages in the modern market.

In the case of the robotic cell RoboMill, several furniture processing functions are performed in one place. The example of the furniture company Medienos era shows that it takes time to move components to another location. The robot carpenter also makes better use of the production area when performing the functions of several devices.

Industrial robot – a solution for businesses that want to control the situation:

• Actively address human resources issues.

• Continuously increase competitive advantage.

• Carry out active development of the company.

Interested in the opportunity to increase the productivity of furniture production? Contact us and we will find the most suitable solution!