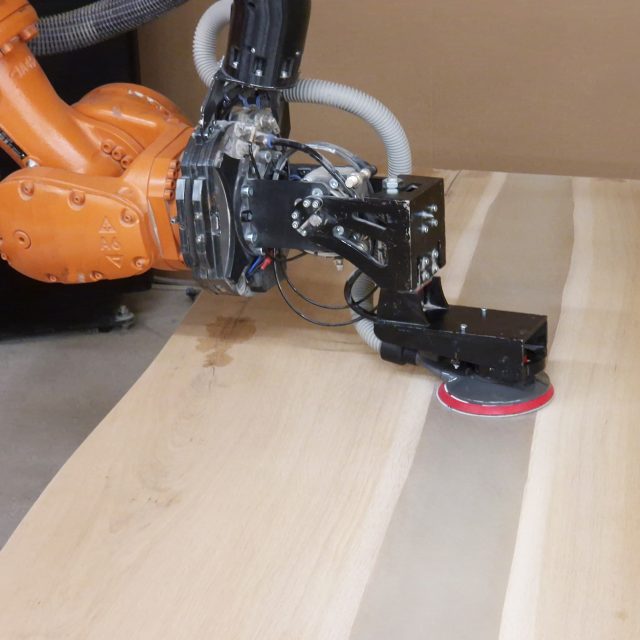

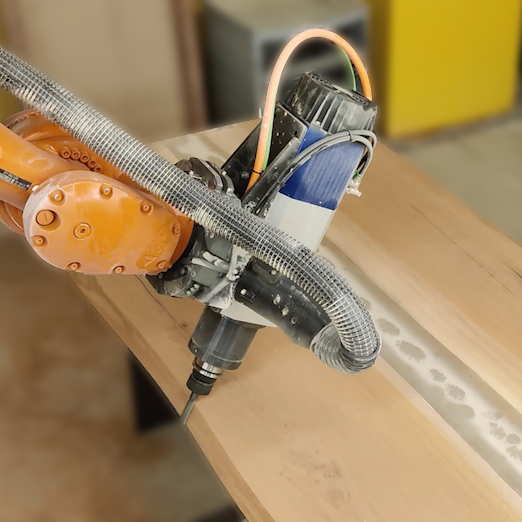

An industrial sanding robot at the furniture manufacturing company MEDIENOS ERA

An industrial sanding robot at the furniture manufacturing company MEDIENOS ERA

Grinding and polishing operations in manufacturing companies are time-consuming and exhausting tasks, and MEDIENOS ERA is no exception. It used to take workers around 8 hours to polish epoxy gaps of solid wood tables in order to create transparent gloss. However, by implementing the RoboSand solution and transferring this lengthy and tiring task to an industrial robot, the operation time has been reduced to 2 hours. This solution allowed the company to increase productivity, improve working conditions, and reduce manual labor.

Since MEDIENOS ERA engages in small-batch furniture production, the software of the RoboSand robotic cell must be user-friendly and not require any specific knowledge of robotics or programming. The software should enable the quick setup of the robot for a new batch within minutes.

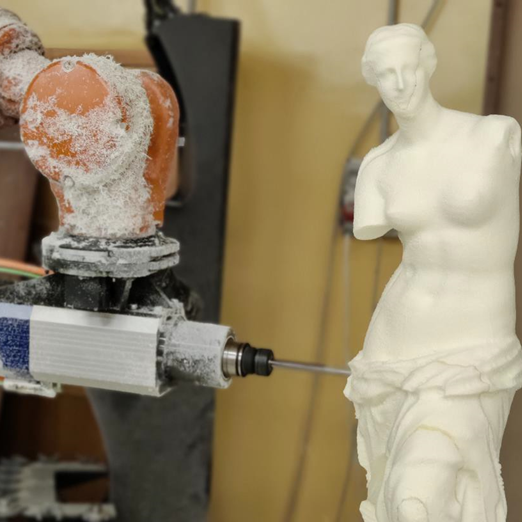

To maximise the autonomy of the RoboSand cell, the automatic replacement station of sanding pad is installed, ensuring uninterrupted operation of the robot during the grinding process. Additionally, to leverage the capabilities of the robot and accelerate return on investment, the cell is equipped with the electric spindle that has an automatic tool changer. This option transforms the robot into a 6-axis CNC machine and enables not only grinding and polishing operations but also drilling, milling, drum sanding, cutting, and more.

Advantages of using the industrial robot RoboSand:

- Quick task assignment to the robot allows to apply the solution to small batches or non-standard products that require long operation times.

- Improved working conditions in furniture manufacturing, reducing the number of tasks associated with high dust levels and constant physical strain.

- Autonomous operation 24 hours a day, 7 days a week, without any breaks.

- Consistent quality and performance of operations.

- Time is saved in production by avoiding slowdowns caused by physical fatigue and strain.

- Optimal utilisation of sanding pads, applying the optimal pressure and speed, and avoiding frequent pad changes.

- The company MEDIENOS ERA, with its extensive experience in furniture manufacturing, demonstrates a strategic approach – the shortage of certain production workers is expected to increase in the future.

The younger generation is not inclined to perform monotonous tasks that require high physical exertion, such as sanding. By employing industrial robots in furniture production, the company can create more attractive job positions. Collaborating with robots which perform sanding functions, reduce employees’ fatigue, and provide an opportunity to perform higher value-added, creative tasks.

MEDIENOS ERA successfully applies other robotic solutions as well: